SMD machine is a high-precision, high-speed, fully automated PCB circuit board mounting equipment, is the key, intelligent equipment in the entire SMT production line. The quality of the SMT machine depends on the equipment to carry out the quality of the main accessories issues and the relevant software intelligence and optimization, we here mainly to introduce you to the LONGTING SMT pick and place machines what the main accessories are.

- Feeder

Feeder, the chip mounter will pick up the components on the feeder in a designated different position, and then mount. As one of the important parts of the mounter, the feeder has a great influence on the production effectiveness and accuracy of the mounter. There are many ways to classify the feeder, such as belt, tray, bulk box, tube; it can also be divided into electric and pneumatic types. The cost of electric feeder is higher than pneumatic feeder, but the stability and durability is higher and can be equipped with 0201. Based on the components quantity, a big batch of feeders may needed.

2. Nozzle

Chip machine nozzle is also one of the important parts of the chip machine business, used to absorb and place components. The use of network information for the role of vacuum adsorption research constantly absorbing, and then use high air pressure to place the components. The work of different components requires us to use different suction nozzles.

3. Screw, guide rail, drive control motor

Screw, guide rail and drive motor are the important components of smt machine xy axis movement mechanism. At present, the quality management of domestic accessories is not as good as the quality of products from Chinese importers. Imported accessories have high effect, high precision, high rigidity, high durability, low noise, etc. The screws and rails also need regular maintenance.

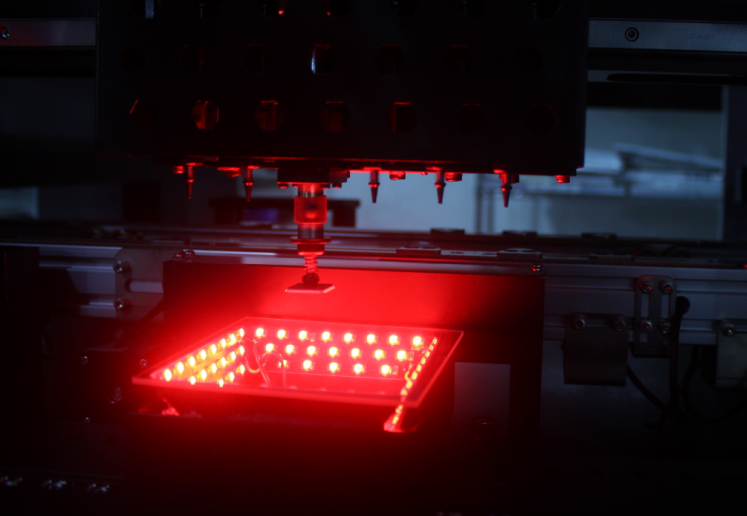

4. Visual system

SMT machine vision system determines the accuracy and stability of SMT amounting process. SMT machine vision system generally consists of two types of cameras. Marker cameras are used to capture the coordinates of the PCB system and check the offset between the camera element and the nozzle. The machine vision system guarantees and corrects the machine vision accuracy by precision camera, light source, image acquisition card and processing system, now the Flying camera technology used in vision system.

5. Industrial computer, vacuum signal generator, photoelectric information sensor, cylinder, conveyor belt, etc.

For LONGTING SMT pick and place machine models: LT4, LT6, LT8, LT10, www.longtingsmt.com, Automatic optimization algorithm based on mathematical modeling and massive empirical data to achieve the best pickup method and movement path, effectively improving placement efficiency by 50%. Self-developed the software, Flying camera Vision, Servo Control and System Accuracy Compensation technologies ensuring your SMT solutions in advanced Markets to go to contact www.longtingsmt.com for have more……

——-By Jessica Hou

Sales from www.longtingsmt.com